3D Scanning and Printing¶

This week group assignment is to test our lab 3D printers.

First Test¶

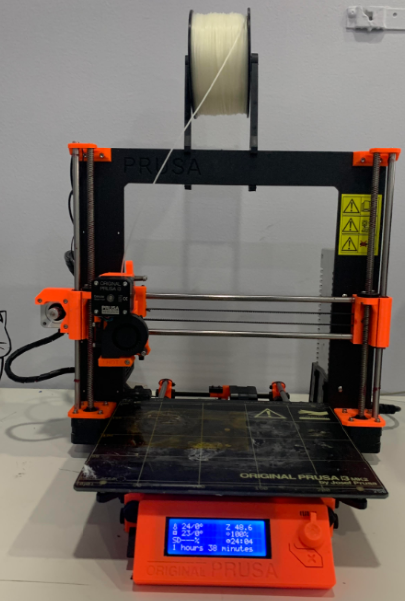

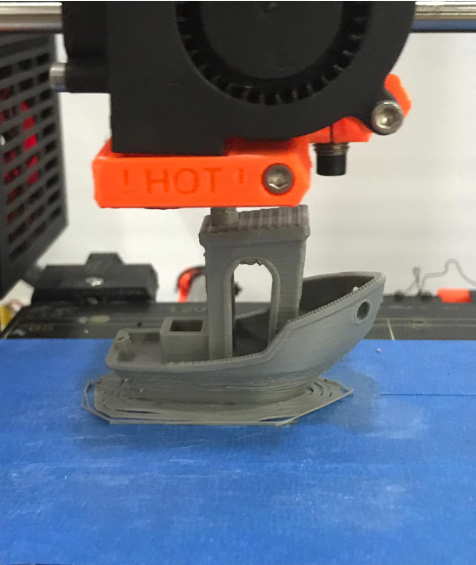

First test was the jolly 3D printing torture-test , which we had printed using three different filament materials PETG, ABS, and Nylon. This design test was chosen because it is small in size and therefore can be printed in less time than other tests. The printer we used for this test is Prusa MK2.

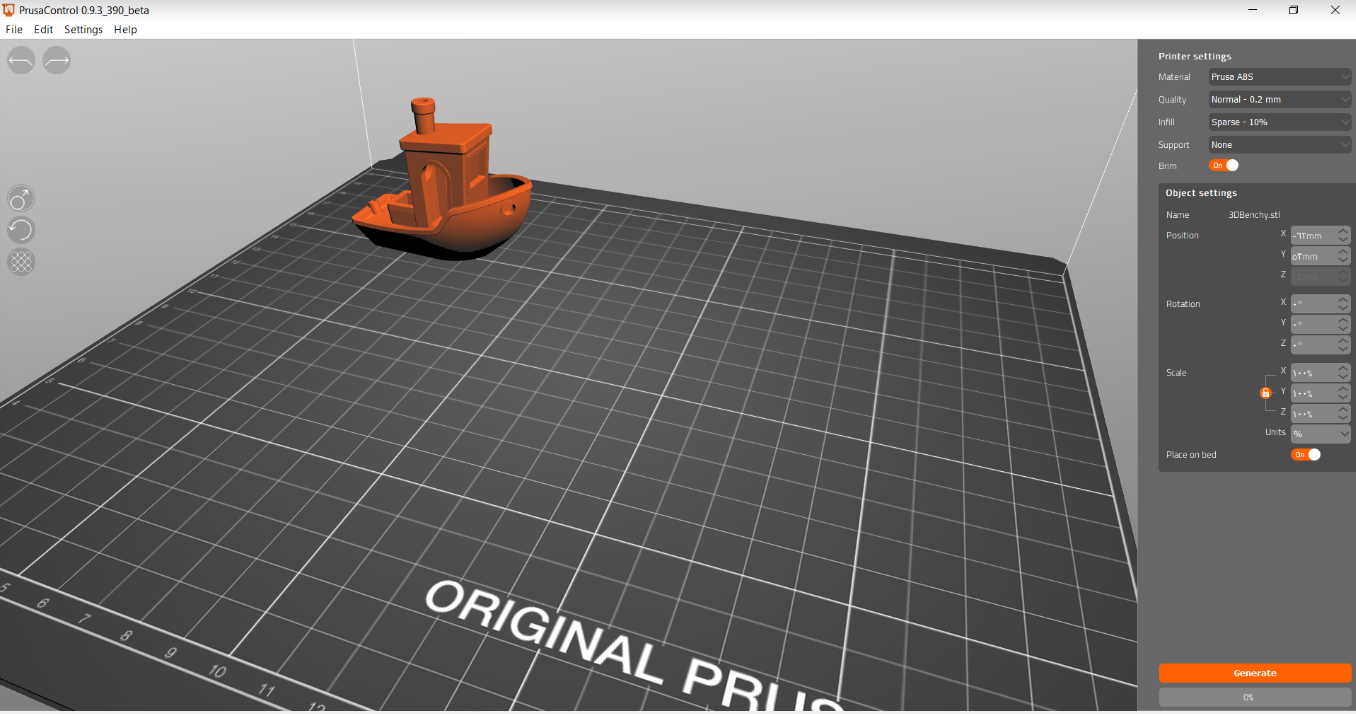

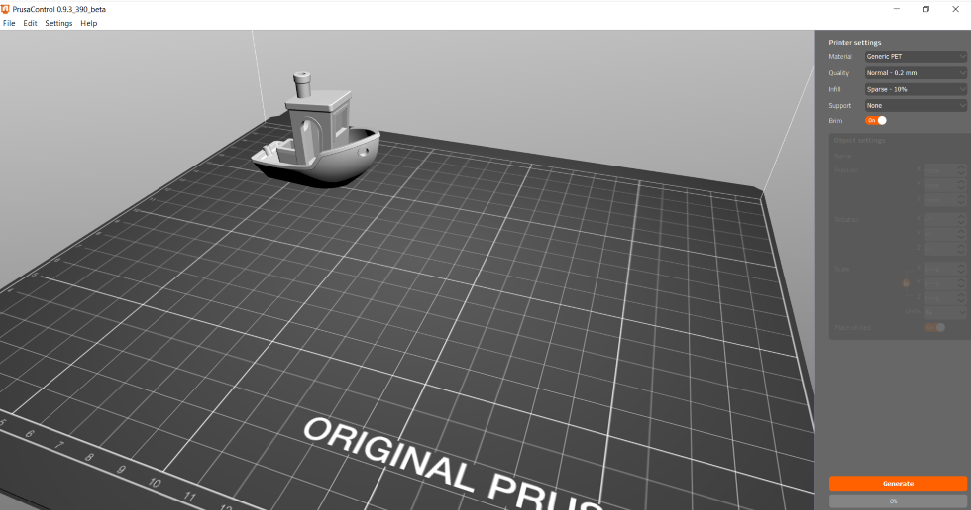

First, we downloaded the stl design file from Thingiverse and imported to PrusaControl software. Then we added the printer settings as per recommended in this website.

For ABS material:

For PETG material:

Then we clicked Generate to generate the G-code.

The G-code is then saved in a SD card and inserted into the Prusa 3D printer.

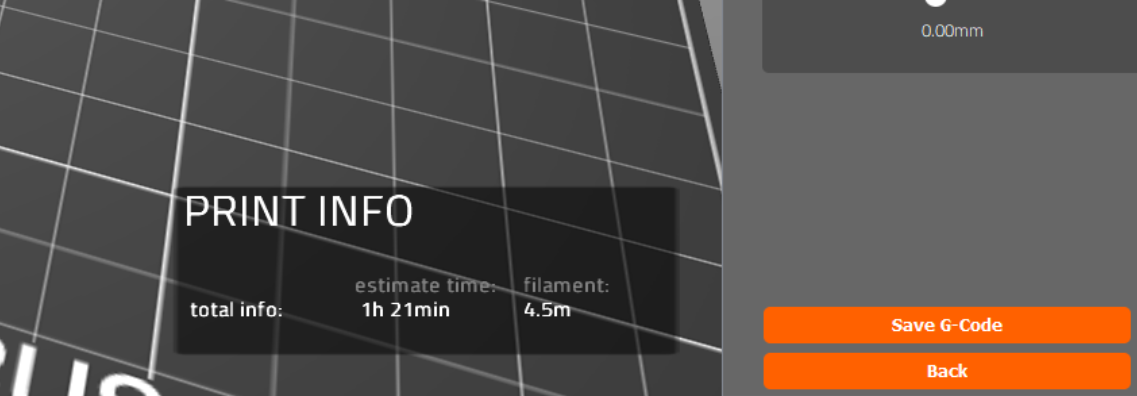

For ABS material: Estimated printing time is shown as 1h and 21min and filament is 4.5m

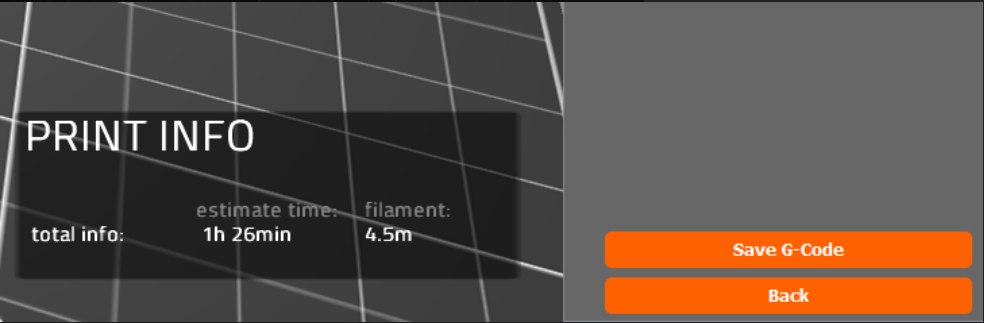

For PETG material: Estimated printing time is shown as 1h and 26min and filament is 4.5m

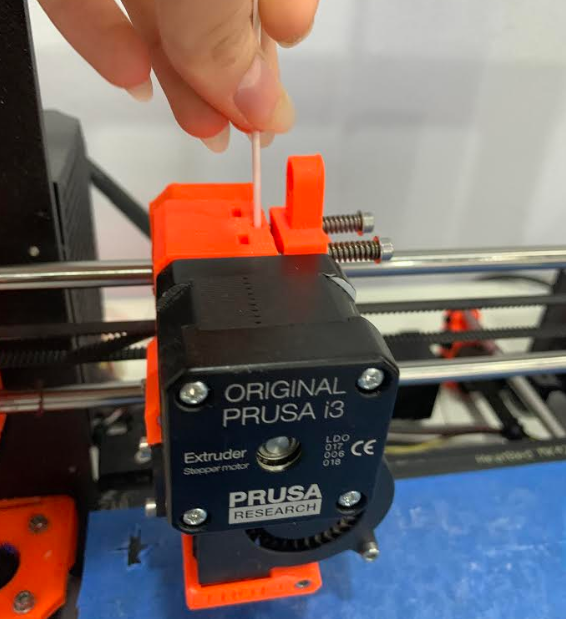

Then 3D printer was turned on and filament was added to the extruder.

Bed and extruder toke time to heat to the required temperature.

After heating process, the 3D printer is ready for printing.

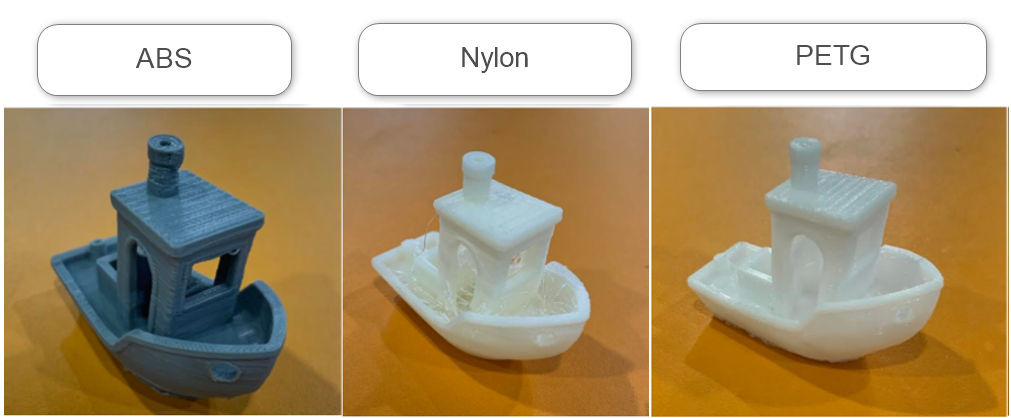

And here is the result for the 3D printing using ABS filament, which shows a smooth and consistent upper layers but imperfections lower layers with lots of blobs and lines.

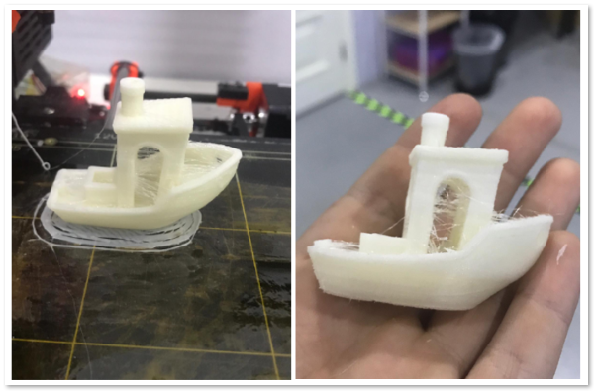

Result using Nylon filament stringing print as the filament hang between the printed object parts.

And here is the reuslts for the three different filaments used:

We found that the print test using Prusa MK2 with PETG filament was the best.

| No | Test name | Actual value | ABS | Nylon | PETG |

|---|---|---|---|---|---|

| 1 | Bridge roof length | 23mm | 23mm | 23mm | 23mm |

| 2 | Chimney roundness | inner diameter 3mm, outer diameter 7mm, hole depth 11mm | inner diameter 2mm, outer diameter 6mm, hole depth 10mm | inner diameter 3mm, outer diameter 7mm, hole depth 10mm | inner diameter 3mm, outer diameter 7mm, hole depth 10mm |

| 3 | Horizontal overall-length | 60mm | 60mm | 61mm | 61mm |

| 4 | Horizontal overall-width | 31mm | 31mm | 31mm | 31mm |

| 5 | Vertical overall-height | overall-height from top to bottom 48mm, height from top of the box to bottom 15.5mm | overall-height from top to bottom 48.5mm, height from top of the box to bottom 16mm | overall-height from top to bottom 48.5mm, height from top of the box to bottom 15.5mm. | overall-height from top to bottom 49mm, height from top of the box to bottom 16mm |

| 6 | Cargo-box size | outside: 12 x 10.81mm, inside : 8 x 7mm, depth: 9mm | outside: 12 x 10.5mm, inside : 8 x 7mm, depth: 9mm | outside: 12 x 10.9mm, inside : 8 x 7mm, depth: 9mm | outside: 12 x 11mm, inside : 8 x 7mm, depth: 9mm |

| 7 | Hawsepipe diameter | inner diameter: 4mm, depth: 0.3mm | inner diameter: 4mm, depth: 0.3mm | inner diameter: 4mm, depth: 1mm | inner diameter: 4mm, depth: 0.5mm |

| 8 | Bridge front window size | 10.5 x 9.5mm | 10.2 x 9.3mm | 10.5 x 9.5mm | 10.5 x 9.3mm |

| 9 | Bridge rear window size | inner diameter: 9mm, outer diameter: 12mm, depth: 0.3mm | inner diameter: 9mm, outer diameter: 12mm, depth: 0.3mm | inner diameter: 9mm, outer diameter: 12.5mm | inner diameter: 9mm, outer diameter: 12.5mm |

| 10 | Small-detail stern nameplate | 0.1mm | unclear | unclear | unclear |

Second Test¶

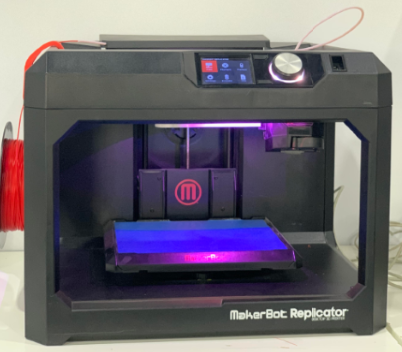

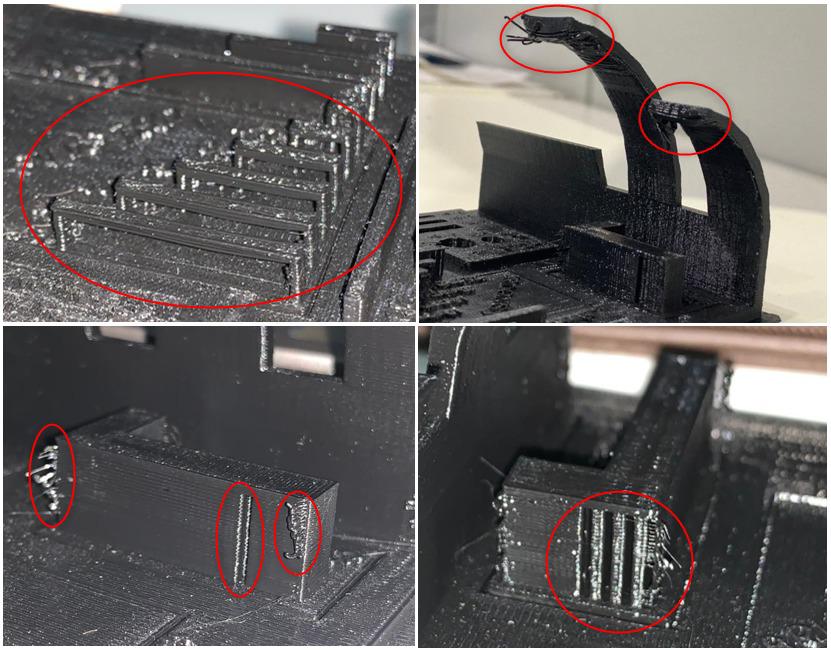

Our second test was using MakerBot 5th Generation 3D printer with PLA filament.

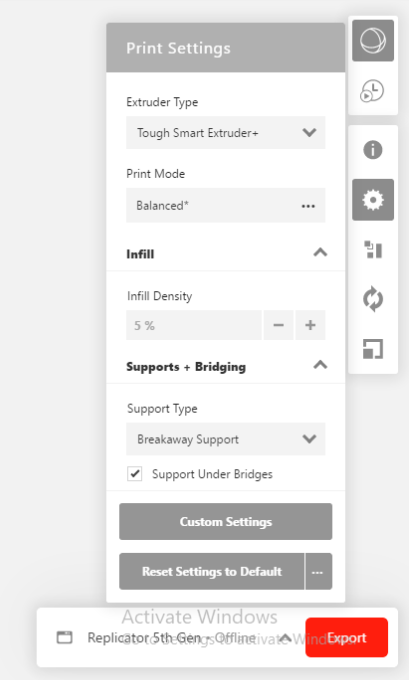

The design we chose for this test was larger in size and required more printing time and filament. It can test multiple things including overhangs, bridges, stringing, extrusion, temperature, and belt tension. You can find the design file here. We have imported the stl file to MakerBot Print software and set the slicing settings as following:

Slicer preview:

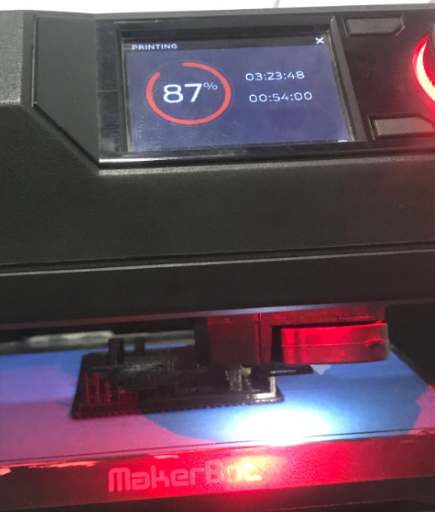

While printing:

Results table:

| No | Test name | Actual value | Test result |

|---|---|---|---|

| 1 | Short overhang test | 15 to 75 degree | 15 to 45 degree is good |

| 2 | Long overhang test | 10 to 80 degree | 10 to 50 degree is good |

| 3 | Hole test | 4mm, 6mm, 8mm diameter | 4mm, 6mm, 8mm diameter |

| 4 | Rectangle test | 4mm, 3mm, 2mm long | 4mm, 3mm, 2mm long |

| 5 | Bridging test | 2mm, 5mm, 10mm, 15mm, 20mm, 25mm long | 4mm, 7mm, 12mm, 17mm, 22mm, 27mm long |

| 6 | Scale test (horizontal) | 10mm, 20mm, 30mm long | 10mm, 20mm, 30mm long |

| 7 | Scale test (vertical) | 10mm, 20mm, 30mm long | 10mm, 20mm, 30mm long |

| 8 | Diameter test | 4mm, 6mm, 8mm, 10mm diameter | 4mm, 5mm, 7mm, 10mm diameter |

| 9 | Support test | - | Oozing |

Final 3D print result:

Problems¶

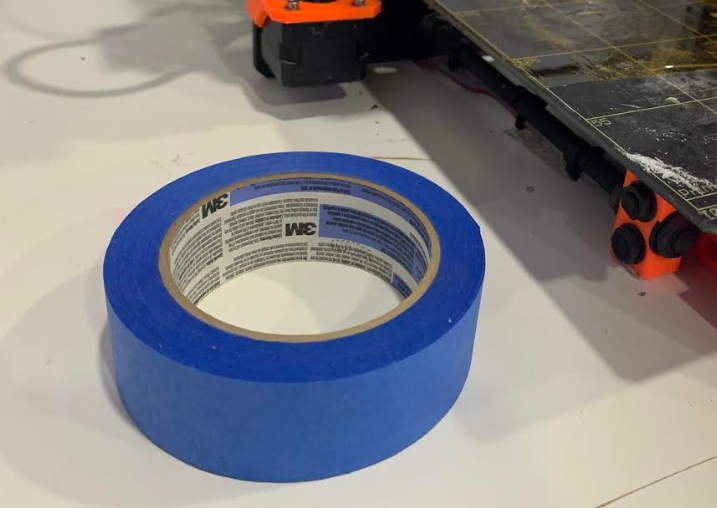

While testing, we had one problem with Prusa MK2 printer. Some of the filament materials like the PETG and nylon were not sticking well on the printer bed because they need a high temperature bed to stick on. To overcome this problem and for better print adhesion we added a masking tape on the printer bed.