Moulding and Casting¶

Group Assignment For this week the group assignment is to Review the safety data sheets for each of your molding and casting materials

White Chocolate¶

description¶

White chocolate is a chocolate confection, pale ivory in color, made from cocoa butter, sugar, milk solids and sometimes vanilla.

method¶

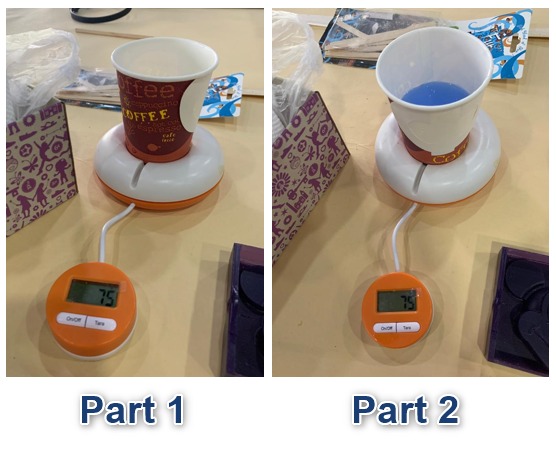

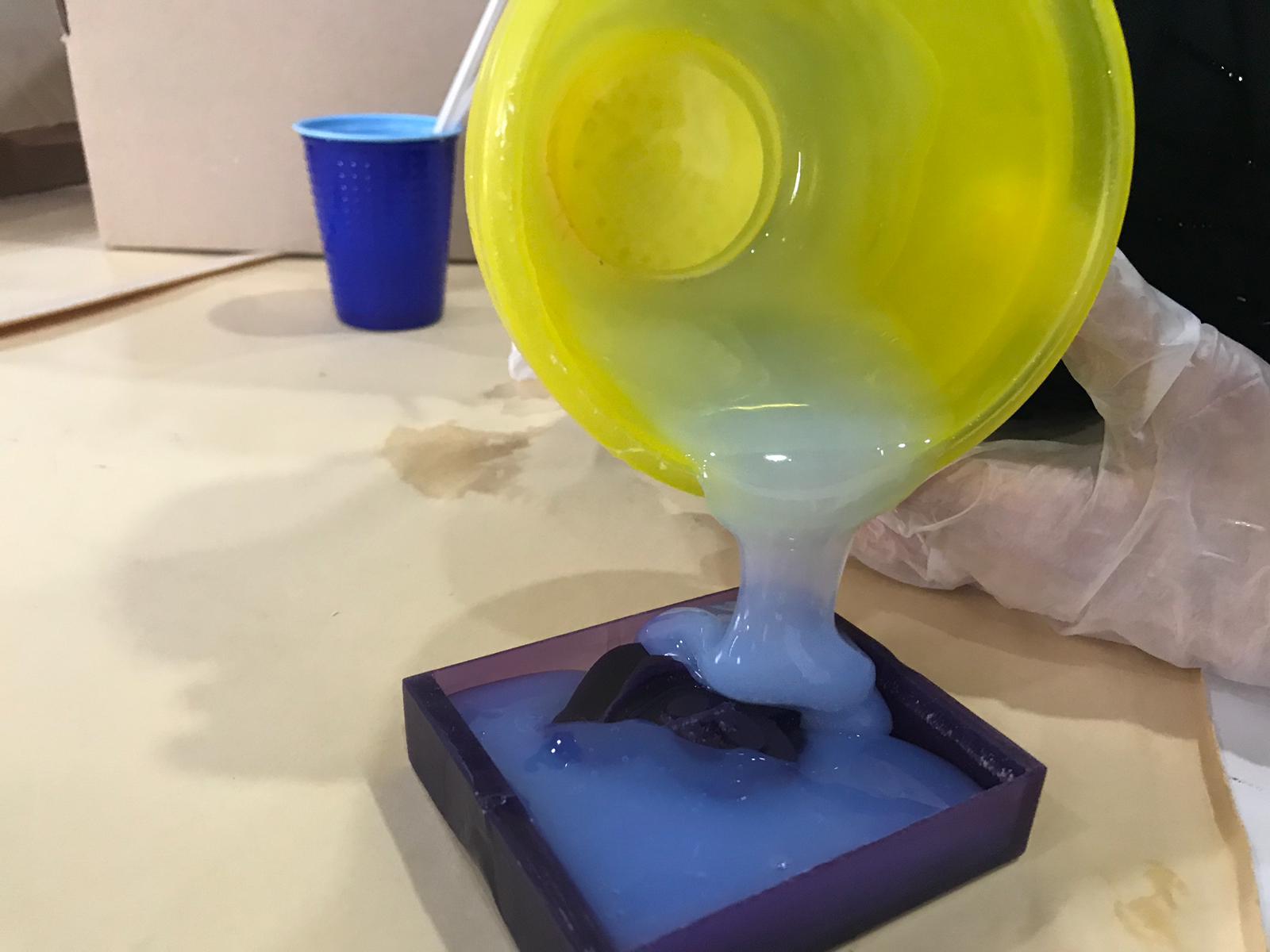

The process for white chocolate is to melt it via a water bath. You take the chocolate chips and put it in a glass then put that in hot water until it melts. And then it can be poured into the mold. Then it can be taken to the fridge to help the cure time.

safety¶

The chocolate is meant to be eaten so it is not a toxic material and can be touched and no extra precuasion is required. Just to avoid touching the hot chocolate directly to avoid burns.

cure time¶

Around 20 to 30 minutes in the fridge and it turns solid.

problems / tips¶

The main problem when dealing with white chocolate is that it hardens very quickly which can be a problem. it needs to be poured into the mold fast before it hardens.

Avoid melting it directly in a pan as it may burn. It can also melt in the microwave but avoid putting it in for long times to avoid burining. A water bath is the safest way to do it without burining the chocolate.

silicone 1¶

Technical Data Sheet

VBS26A Safety data sheet

VBS26B Safety data sheet

description¶

Silicone VBS26-35, which is 2-part addition cure silicone.

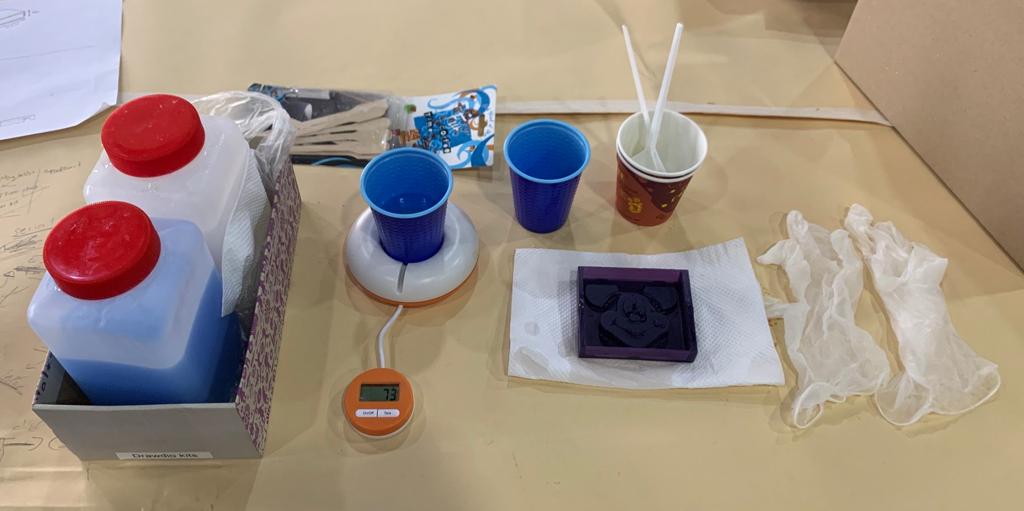

method¶

“2 Part Addition cure silicone moulding rubber” . It has two parts. Use equal amounts of each part.

safety¶

- Do not eat, drink or smoke while using the material.

- Do not touch the material directly by hand, wear rubber gloves before using.

- Material is not safe for food.

cure time¶

Around 5 hours

problems / tips¶

Can form bubbles. Use a heat gun to remove bubbles.

silicone 2¶

description¶

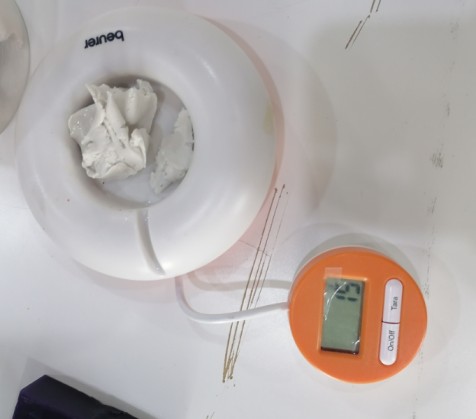

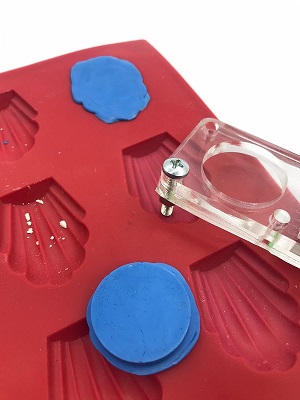

it is a mold putty that has the consistency of cookie dough and is very easy to mix and apply. Created by a chef in order to bring the art of mold making into both commercial and home kitchens.

method¶

It contains two parts, A and B. Use equal amounts of A and B.

Mix them by hand to get until you get a homogeneous color.

Take a small amount of the silicone mixture and try to cover the small detiles and then put then cover the design with the rest of the mixed silicone.

safety¶

This material is foodsafe and can be handled by hands directly.

cure time¶

around 2 hours.

problems / tips¶

When pouring this material into the scilicon shell mold used for all other tests. It solidified inside and did not get out. We also used it on a acrylic mold and it was possible to pull that one out. Do not use in scilicone molds.

epoxy¶

description¶

Zemco Epoxy Resin.High viscosity resin for Art, Wood and Floor. Mixing Ratio A-100g =B-33g.

method¶

epoxy 1/3 ratio where it is 75% of resin and 25% hardner. mix them together. pour the epoxy.

safety¶

- use gloves.

- use in well ventilated area.

cure time¶

12 hours.

problems / tips¶

use heatgun to get out any bubbles.

gypsum¶

description¶

A soft mineral, composed of calcium sulfate dihydrate, used in wallboards, plaster of Paris (POP), etc. Sub-varieties of the material, ‘Satin spar’ and ‘Alabaster’, are often used in ornaments and decor pieces such as floor or wall trims.

method¶

1 part gypsum powder to 1 part water. There are different ratios that would work as well depending on the type of gypsum.

safety¶

Avoid inhaling the powder. Safe to touch.

cure time¶

2-4 hours

problems / tips¶

It can be easy to mess up the mix ratio and get a weak cast that comes apart easily. Soak the powder in the water for 30 seconds before mixing for better results. dont over mix. Stop mixing when the clumps dissapear and pour.